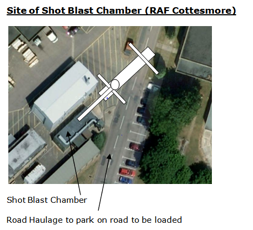

October 2012 Our client approached Flexitrans to transport and project manage the movement of a decommissioned shot blasting unit from an RAF Base, located in Cottesmore, Lincolnshire to their premises in Central West London.

October 2012 Our client approached Flexitrans to transport and project manage the movement of a decommissioned shot blasting unit from an RAF Base, located in Cottesmore, Lincolnshire to their premises in Central West London.

Requirements:

- To project manage whole movement with MOD authorities, clients and subcontractors and provide safety/method statements

- Supply crane and labour to lift items from floor onto road equipment

- Supply suitable UK road haulage to safely move items from RAF Cottesmore, Lincolnshire to receivers site in West Central London

- Arrange/provide abnormal load route for wide load and liaison with relevant Police Constabularies

- Arrange/negotiate partial road closure streets en-route to final delivery address with local London Borough Council

- Liaise with local neighbourhood to ensure smooth running of the movement

- Supply crane and labour to lift off items from road equipment to floor of receivers site

The main package measured of 12.80 x 4.75 x 3.30 mtrs – with an approximate weight of 12,000 kgs plus some smaller ancillary items that would make up a full load.

The length, height and weight of the main package was not the issue, the width was the challenge, especially having to negotiate some narrow roads on the approach to the delivery point.

The narrowest road tapered from 7.00 mtrs in width with parked cars on either side to just 4.00 mtrs wide plus overhanging trees! Allowing for car widths of approximately 2.00 mtrs wide, it didn’t leave much room for our load, so it was necessary to negotiate parking restrictions and road closures with the local Borough Council.

Once safely arrived inside the receiver’s site the next obstacle was to get the package to its final installation place. Access around the outside of the client’s factory was not possible due to width restrictions, so we had to go through their factory.

Their front door clearance was 4.90 mtrs but the clearance of their rear door was only 4.00 mtrs. The running height of the package loaded on our road trailer was 4.75 mtrs. So -as the receiver was railway industry based- we simply offloaded the package from our trailer using hydraulic jacks on to a specially fabricated/designed railway bogeys that was then hauled by the clients own railway locomotive through their factory/workshop.

Positioned at the rear of their site near to the final installation location we then lifted the package by 100T mobile crane.

Job done!